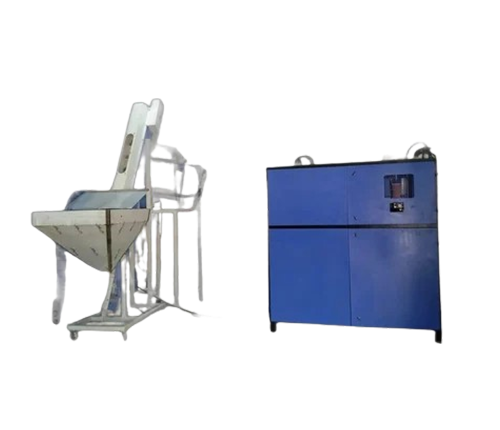

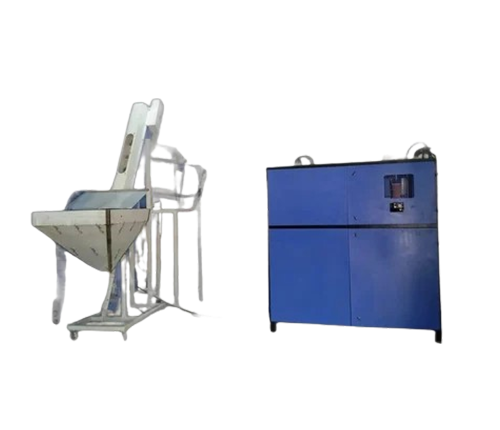

2 Cavity Automatic PET Stretch Blow Moulding Machine

Product Details:

| Automation Grade | Automatic |

| Model Name/Number | BCM – 2L2C |

| Mould Cavity | 2 cavity |

| Material | Mild Steel |

| Blowing Pressure | 30 Kg/cm |

| Mould Thickness | 180 mm |

| Height | 400 mm (Max) |

| Outer Diameter | 100 mm |

| Cavity Pitch | 130 mm |

| Stretching Stroke | 450 mm (Max) |

| Operating Pressure | 8 Kg/cm |

| Theoretical Production | 2300 Pieces Per Hour |

| Heating Power | 32 kW |

| Neck Outer Diameter | 19 to 30 mm |

| Clamping Stroke | 170 mm (Max) |

| Containers Volume | 100 ml (Min), 2000 ml (Max) |

Features:

- Compact Design enables saving of Space.

- Premium HMI 7 inches Siemens PLC enables Touch Screen Control.

- PLC programmed to provide valuable Productivity data.

- Specially designed Ejector and Loading Arms.

- Sturdy Infrared heating system and Highly precise Blow Mould closing system ensures High Quality Blowing.

- Low consumption of electricity, air and water.

- Specially designed inbuilt Air recovery system to enable power saving.

- High Quality Valves and Cylinders for long trouble free production.

- High Quality IMI Norgen blowing valves for long trouble free performance.

- Special Wedge lock for firm Clamping.

- Special Sensors to ensure Moulds do not close, if there is no Preform.

- Blowing commences only if Preforms are heated to a pre-set temperature.

- Precise Heating Zones to ensure uniform Heating to a pre-set pattern.

- Consistent production and perfect repeatability.

- Long and trouble free life of the Machine.

- High Intelligence : The machine is controlled through automactic PLC System.

- High Quality : Sturdy infrared heating system and highly precise blow-mould closing system ensure quality.

- Low Cost : Low consumption of electricity, air and water.

- High Transparency : Easy maintenance, absolute safe visual inspection, low noise.

- Safe, reliable, and unique design of the position of valve